Beyond Connectivity: Smarter Tools for Manufacturing’s Frontline

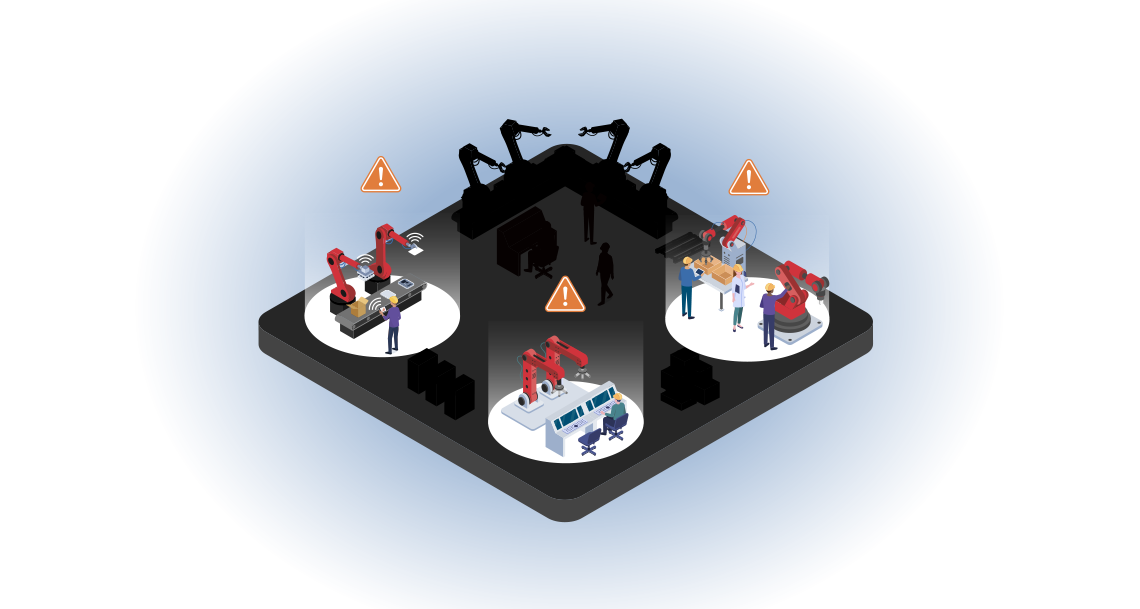

What you don’t see on your shop floor can hurt you. From outdated work instructions to missing real-time feedback, frontline inefficiencies are often hidden in plain sight until they lead to downtime, quality escapes, or compliance risks.

Watch this on-demand webinar to discover the hidden gaps in workforce execution that silently erode performance. See how a purpose-built, workforce-centric solution, without coding or complexity, can empower your operators, supervisors, and quality teams to work smarter, faster, and more accurately.

Why watch?:

- 42% of manufacturers cite workforce execution visibility as their top challenge

- 70% of quality issues stem from human-driven process breakdowns

- Disconnected operations cost manufacturers $17,000-$30,000 per frontline employee per year

What you'll learn:

- The top five workforce execution blind spots hurting your performance and how to eliminate them

- Why most “connected worker” tools only digitize tasks, not decisions

- A live demo showing how a unified digital environment improves quality, speed, and compliance on day one

- And more