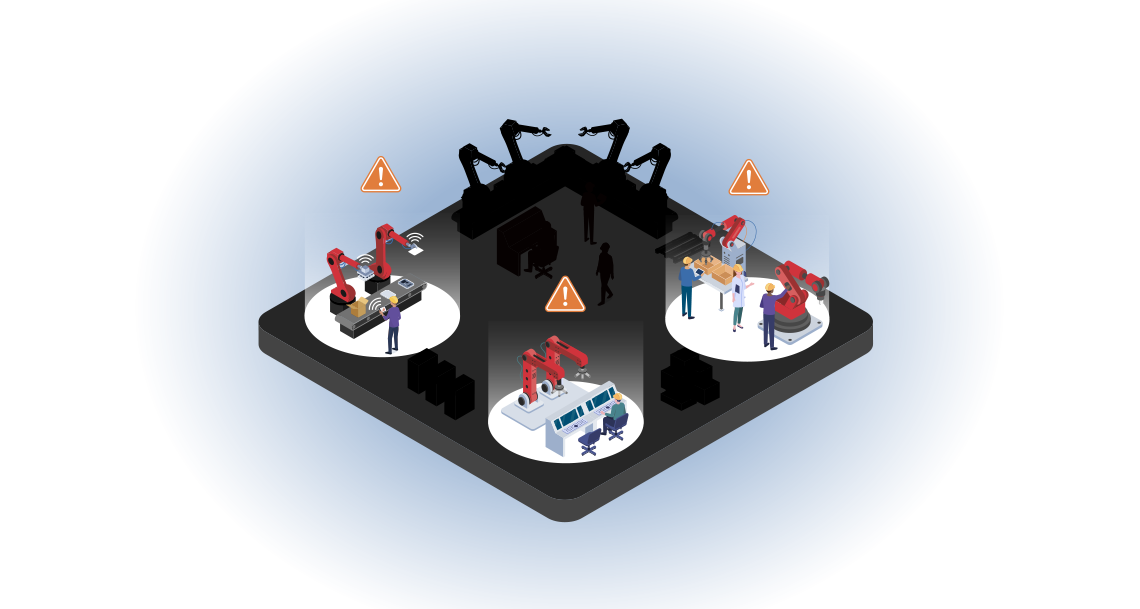

What you don’t see on your shop floor can hurt you. From outdated work instructions to missing real-time feedback, frontline inefficiencies are often hidden in plain sight—until they lead to downtime, quality escapes, or compliance risks.

Join this interactive session to uncover the hidden gaps in workforce execution that silently erode performance—and discover how a purpose-built, workforce-centric solution, without coding or complexity, can empower your operators, supervisors, and quality teams to work smarter, faster, and more accurately.

Why attend:

- 42% of manufacturers cite workforce execution visibility as their top challenge

- 70% of quality issues stem from human-driven process breakdowns

- Disconnected operations cost manufacturers $17,000-$30,000 per frontline employee per year

What you'll learn:

- The top five workforce execution blind spots hurting your performance—and how to eliminate them

- Why most “connected worker” tools only digitize tasks, not decisions

- A live demo showing how a unified digital environment improves quality, speed, and compliance on day one

- And more

Reserve your spot and take the first step toward eliminating the silent inefficiencies you can’t afford to ignore.

**Can't make the live event? Make sure to still register so that you get an immediate notification when the webinar recording is available for on-demand viewing.